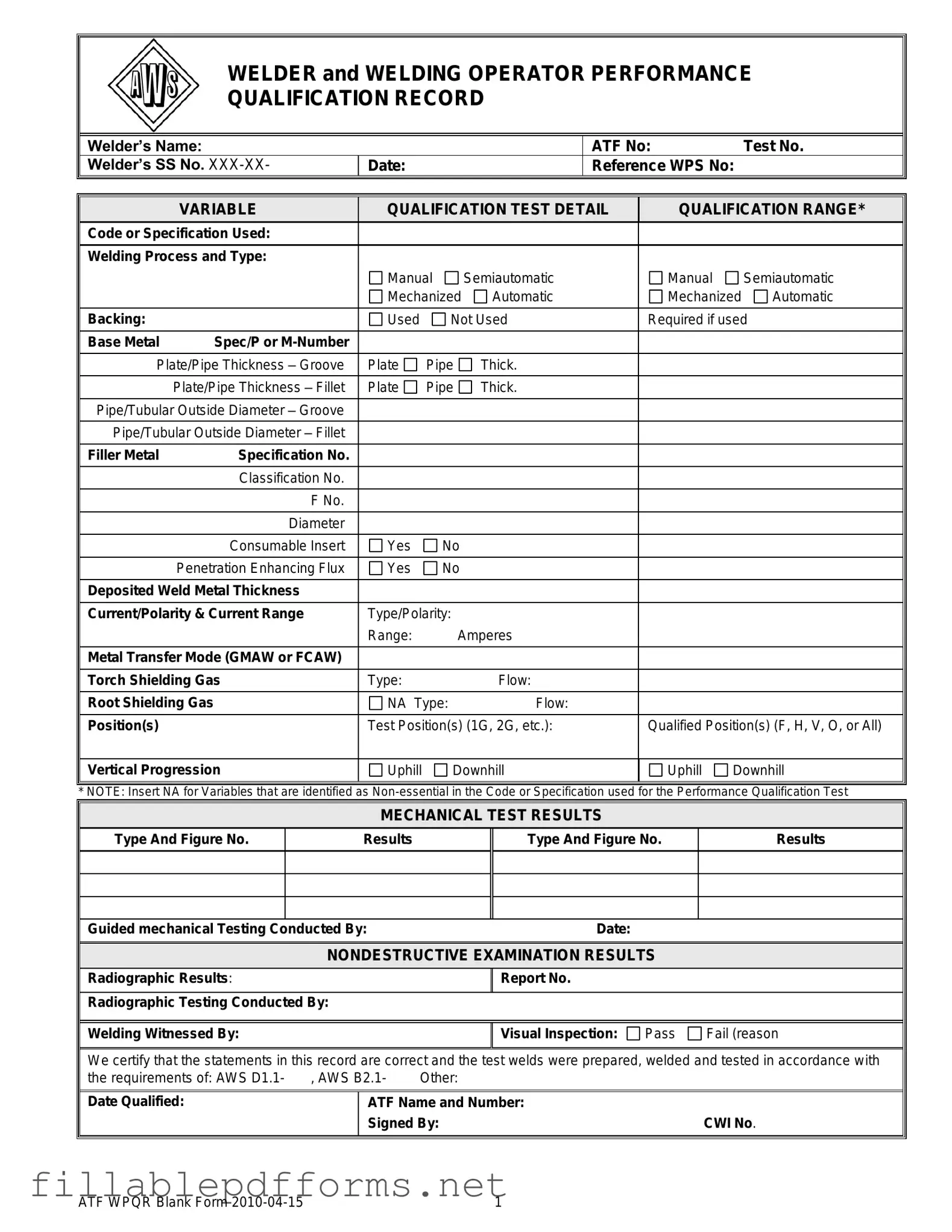

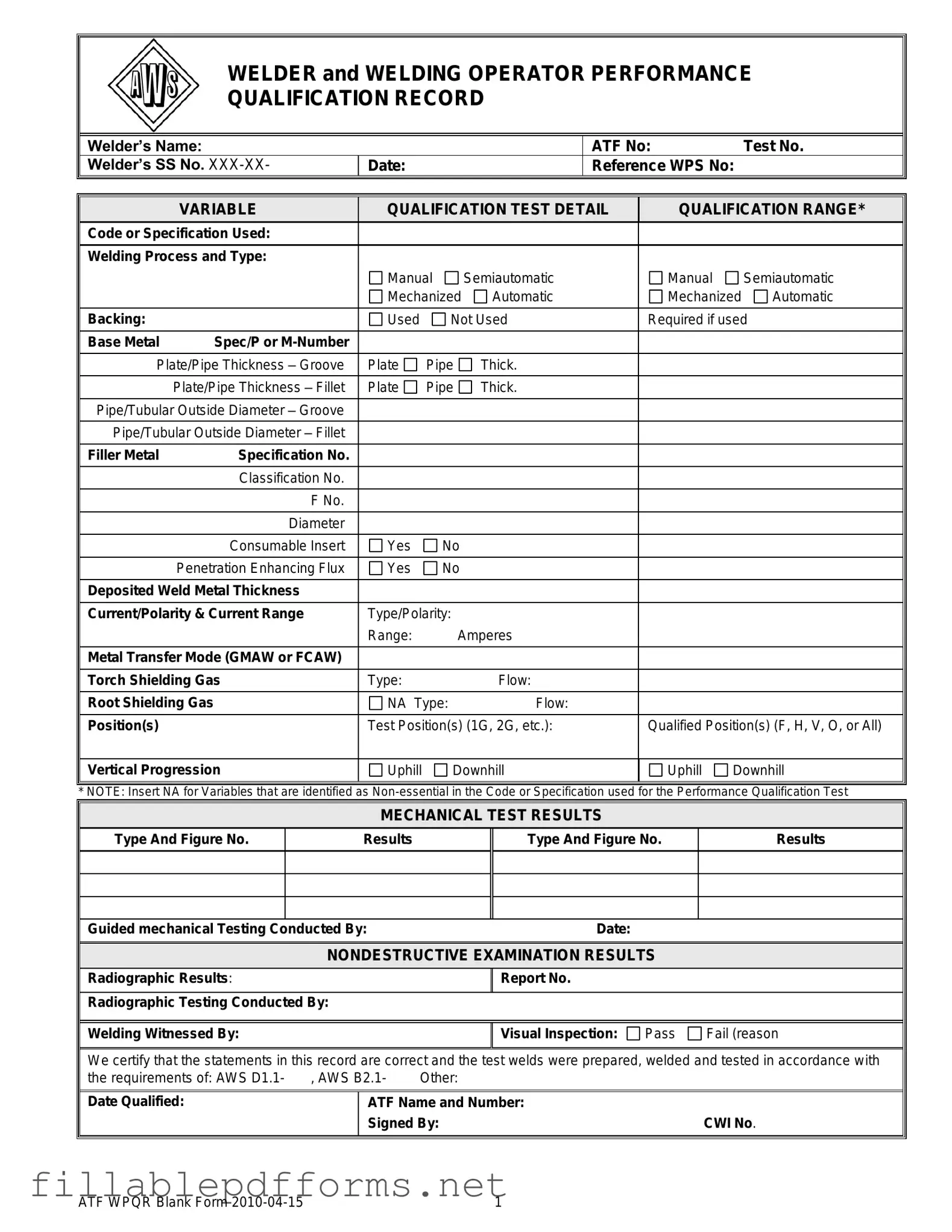

Welder Performance Qualification Record PDF Template

The Welder Performance Qualification Record form is a critical document that verifies a welder's skills and qualifications in various welding processes. It captures essential details such as the welder's name, test results, and the specifications used during qualification tests. This record ensures compliance with industry standards and helps maintain quality and safety in welding practices.

Launch Editor Here

Welder Performance Qualification Record PDF Template

Launch Editor Here

Launch Editor Here

or

▼ Welder Performance Qualification Record PDF

Almost there — finish the form

Complete Welder Performance Qualification Record online fast — no printing, no scanning.